The desire for a more comfortable and rational way of life resulted in a growing application of thermal insulation in the construction industry for residential, public and industrial facilities.

With the intensive work of many experts materials have been found whose composition and physical properties meet the needs for thermal insulation in many ways.

In 1954 the German chemical concern “BASF” patented and started the production of slabs of expanded polystyrene under the trademark Styrofoam. Since then polystyrene has become a synonym for all products from expanded polystyrene.

In practice, the self-extinguishing expanded polystyrene is used for thermal insulation of all types of buildings and structures. Each plate from polystyrene is manufactured in several specific densities (usually 15 to 30 kg/m3).

The Bosnian standard BAS EN13136, which is compliant with the European standard EN13136 prescribes a new way of classifying and labeling products of EPS. As a basis of classification under this standard the compressive strength under 10% deformation is taken.

Each manufacturer is required to declare the product by BAS EN13163 and make sure that the declaration contains all the markings prescribed by this standard.

Product advantages of EPS

- Product advantages of EPS

- Great thermal insulation (λ = 0.032 to 0.041 W / mK)

- Difficult fuels and self-extinguishing material (Reaction to fire E)

- Resistant to temperatures up to 90 degrees

- Good characteristics

- Satisfactory vapor permeability (μ = 20-100)

- Good sound absorber and isolator

- Satisfactory vapor permeability (μ = 20-100)

- Good sound absorber and isolator

- It improves sound insulation of building structures

- Neutral behaves according to concrete, metal, wood

- Extremely little moisture absorption (0.2 to 5.0% by volume)

- Easy assembly and installation

- Easy transportation and handling during installation

- Ecologically and biologically correct product

- without harmful effects on the environment and people

Graphite EPS

We are witnessing a continuing increase in energy prices as the human desire for comfortable living becomes more expensive day by day. Therefore, the construction of low-energy buildings is constantly increasing. These facilities clearly need extremely good thermal insulation.

Therefore, the thickness of insulation is increasing every day. However, this increase in obesity entails an increase in other expenses. With the goal of solving these problems German concern BASF in 1995 patented a new EPS with the addition of graphite. In the initial stage, the GRAPHITE EPS has achieved about 20% better results than the classic EPS (Styropor). Of course it took some time for the patent to be adapted to the industrial application of the same should be for some time so that in Europe a couple of years we have greater and greater application of this new EPS.

It should be noted that new graphite EPS achieves up to 25% better results than classical. Following the progress of engineering and technology, the company EPS LAŠTRO decided that in 2010 its customers a best use of heat insulation material.

Basic features

GRAPHITE EPS (hereinafter referred to as EPS-G) is designed for expanding the polystyrene in which the granules are further enriched with graphite. This graphite has the role of absorption and reflection of infrared radiation, which is an improvement over the conventional EPS.

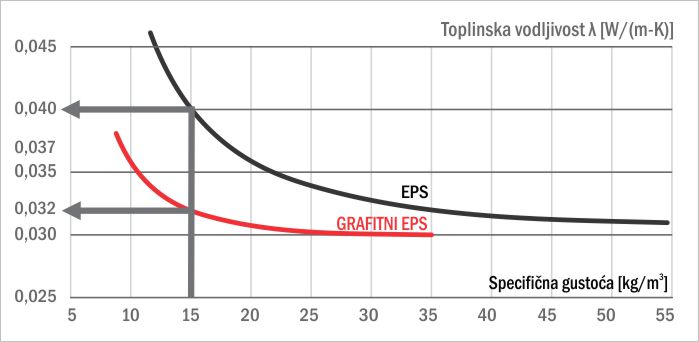

An important fact is that it is an improvement over the conventional EPS largest in densities of about 15 kg / m3.

This can best be seen in the comparative diagram of thermal conductivity depending on the density of the plate.

Ecology

The diagram shows that GRAPHITE EPS with a density of 15 kg / m3 gives better results in terms of thermal insulation than a conventional EPS density of 30 kg / m3 and more. Accordingly, the fact that the same results should be used twice a smaller amount of material speaks for itself what kind of impact in terms of environmental works if used GRAPHITE EPS.

Analysis of the Institute of Ecology and tuff in 2000 in Germany has shown that the graphite EPS by far the best environmentally friendly thermal insulation material.

Application

Of graphite EPS for expansion, it is possible to produce blocks and panels for thermal insulation of different bulk density (just like the classic EPS).

Of course that features specific material and determine its application.

As the largest percentage improvement in densities of 15 kg / m3, this means that this GRAPHITE EPS mainly represented in the façade systems. It also recommended the application of the sloping roof construction. Furthermore, due to the excellent results at low densities it an excellent sound insulation.

According to that facts stated above:

EPS-G can be used in all places on buildings

Most preferred as:

- thermal insulation facade system EPS-GF,

- thermal insulation of pitched roofs EPS-G70.